QUALITY ASSURANCE

“We believe that “Quality is never an accident. It is always the result of intelligent effort”.

Our company is recognized for stringent quality control in each and every step of the manufacturing process. Both the management and the work force of our company are conscious of the need for the highest quality & attention to detail customer care especially critical in today’s competitive environment.

Steel Bars what we are manufacturing are BIS registered and confirms to IS 1786 standards & we issue test certificate to each & every lot supplied, only after thoroughly checking in our lab. Our Brand Steel bars have been awarded “The Best TMT steel for the year 2006” in India. We also have Certificate of recognition, Star Export House from Government of India, Ministry of Commerce & Industry, which makes us eligible to Export our brand Steel. This clearly shows how superior and advanced our quality is.

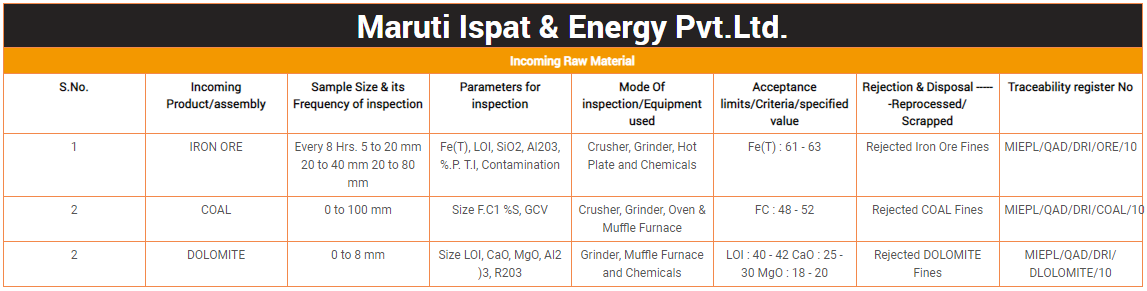

Maruti Ispat & Energy Pvt.Ltd. |

|||||||

|---|---|---|---|---|---|---|---|

| Incoming Raw Material | |||||||

| S.No. | Incoming Product/assembly | Sample Size & its Frequency of inspection | Parameters for inspection | Mode Of inspection/Equipment used | Acceptance limits/Criteria/specified value | Rejection & Disposal ------Reprocessed/ Scrapped | Traceability register No |

| 1 | IRON ORE | Every 8 Hrs. 5 to 20 mm 20 to 40 mm 20 to 80 mm | Fe(T), LOI, SiO2, Al203, %.P. T.I, Contamination | Crusher, Grinder, Hot Plate and Chemicals | Fe(T) : 61 - 63 | Rejected Iron Ore Fines | MIEPL/QAD/DRI/ORE/10 |

| 2 | COAL | 0 to 100 mm | Size F.C1 %S, GCV | Crusher, Grinder, Oven & Muffle Furnace | FC : 48 - 52 | Rejected COAL Fines | MIEPL/QAD/DRI/COAL/10 |

| 2 | DOLOMITE | 0 to 8 mm | Size LOI, CaO, MgO, Al2 )3, R203 | Grinder, Muffle Furnace and Chemicals | LOI : 40 - 42 CaO : 25 - 30 MgO : 18 - 20 | Rejected DOLOMITE Fines | MIEPL/QAD/DRI/ DLOLOMITE/10 |

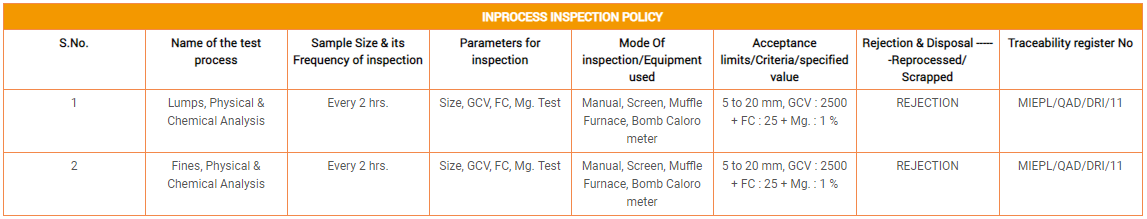

| INPROCESS INSPECTION POLICY | |||||||

|---|---|---|---|---|---|---|---|

| S.No. | Name of the test process | Sample Size & its Frequency of inspection | Parameters for inspection | Mode Of inspection/Equipment used | Acceptance limits/Criteria/specified value | Rejection & Disposal ------Reprocessed/ Scrapped | Traceability register No |

| 1 | Lumps, Physical & Chemical Analysis | Every 2 hrs. | Size, GCV, FC, Mg. Test | Manual, Screen, Muffle Furnace, Bomb Caloro meter | 5 to 20 mm, GCV : 2500 + FC : 25 + Mg. : 1 % | REJECTION | MIEPL/QAD/DRI/11 |

| 2 | Fines, Physical & Chemical Analysis | Every 2 hrs. | Size, GCV, FC, Mg. Test | Manual, Screen, Muffle Furnace, Bomb Caloro meter | 5 to 20 mm, GCV : 2500 + FC : 25 + Mg. : 1 % | REJECTION | MIEPL/QAD/DRI/11 |

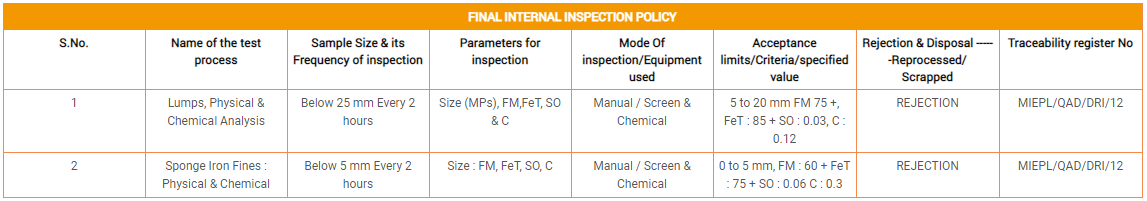

| FINAL INTERNAL INSPECTION POLICY | |||||||

|---|---|---|---|---|---|---|---|

| S.No. | Name of the test process | Sample Size & its Frequency of inspection | Parameters for inspection | Mode Of inspection/Equipment used | Acceptance limits/Criteria/specified value | Rejection & Disposal ------Reprocessed/ Scrapped | Traceability register No |

| 1 | Lumps, Physical & Chemical Analysis | Below 25 mm Every 2 hours | Size (MPs), FM,FeT, SO & C | Manual / Screen & Chemical | 5 to 20 mm FM 75 +, FeT : 85 + SO : 0.03, C : 0.12 | REJECTION | MIEPL/QAD/DRI/12 |

| 2 | Sponge Iron Fines : Physical & Chemical | Below 5 mm Every 2 hours | Size : FM, FeT, SO, C | Manual / Screen & Chemical | 0 to 5 mm, FM : 60 + FeT : 75 + SO : 0.06 C : 0.3 | REJECTION | MIEPL/QAD/DRI/12 |

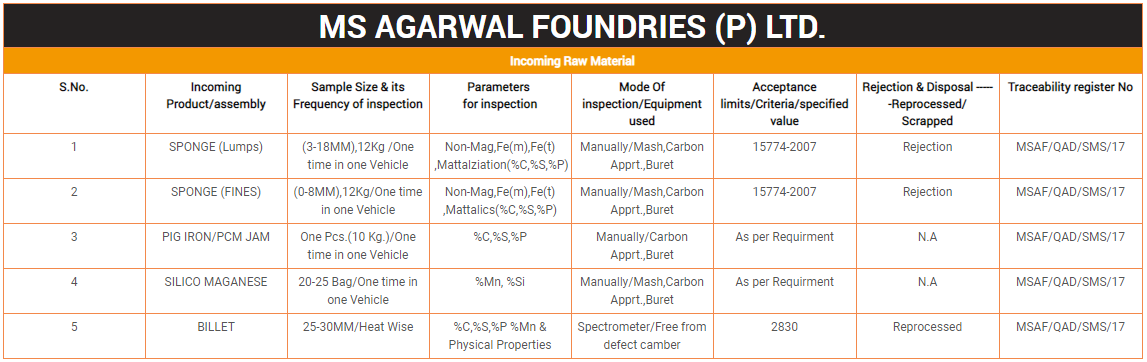

MS AGARWAL FOUNDRIES (P) LTD. |

|||||||

|---|---|---|---|---|---|---|---|

| Incoming Raw Material | |||||||

| S.No. | Incoming Product/assembly | Sample Size & its Frequency of inspection | Parameters for inspection | Mode Of inspection/Equipment used | Acceptance limits/Criteria/specified value | Rejection & Disposal ------Reprocessed/ Scrapped | Traceability register No |

| 1 | SPONGE (Lumps) | (3-18MM),12Kg /One time in one Vehicle | Non-Mag,Fe(m),Fe(t),Mattalziation(%C,%S,%P) | Manually/Mash,Carbon Apprt.,Buret | 15774-2007 | Rejection | MSAF/QAD/SMS/17 |

| 2 | SPONGE (FINES) | (0-8MM),12Kg/One time in one Vehicle | Non-Mag,Fe(m),Fe(t),Mattalics(%C,%S,%P) | Manually/Mash,Carbon Apprt.,Buret | 15774-2007 | Rejection | MSAF/QAD/SMS/17 |

| 3 | PIG IRON/PCM JAM | One Pcs.(10 Kg.)/One time in one Vehicle | %C,%S,%P | Manually/Carbon Apprt.,Buret | As per Requirment | N.A | MSAF/QAD/SMS/17 |

| 4 | SILICO MAGANESE | 20-25 Bag/One time in one Vehicle | %Mn, %Si | Manually/Mash,Carbon Apprt.,Buret | As per Requirment | N.A | MSAF/QAD/SMS/17 |

| 5 | BILLET | 25-30MM/Heat Wise | %C,%S,%P %Mn & Physical Properties | Spectrometer/Free from defect camber | 2830 | Reprocessed | MSAF/QAD/SMS/17 |

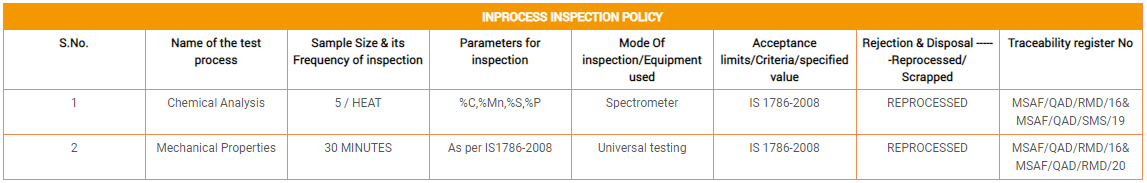

| INPROCESS INSPECTION POLICY | |||||||

|---|---|---|---|---|---|---|---|

| S.No. | Name of the test process | Sample Size & its Frequency of inspection | Parameters for inspection | Mode Of inspection/Equipment used | Acceptance limits/Criteria/specified value | Rejection & Disposal ------Reprocessed/ Scrapped | Traceability register No |

| 1 | Chemical Analysis | 5 / HEAT | %C,%Mn,%S,%P | Spectrometer | IS 1786-2008 | REPROCESSED | MSAF/QAD/RMD/16& MSAF/QAD/SMS/19 |

| 2 | Mechanical Properties | 30 MINUTES | As per IS1786-2008 | Universal testing | IS 1786-2008 | REPROCESSED | MSAF/QAD/RMD/16& MSAF/QAD/RMD/20 |

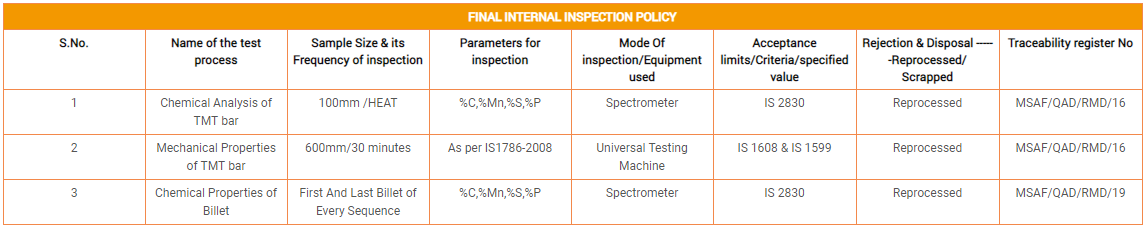

| FINAL INTERNAL INSPECTION POLICY | |||||||

|---|---|---|---|---|---|---|---|

| S.No. | Name of the test process | Sample Size & its Frequency of inspection | Parameters for inspection | Mode Of inspection/Equipment used | Acceptance limits/Criteria/specified value | Rejection & Disposal ------Reprocessed/ Scrapped | Traceability register No |

| 1 | Chemical Analysis of TMT bar | 100mm /HEAT | %C,%Mn,%S,%P | Spectrometer | IS 2830 | Reprocessed | MSAF/QAD/RMD/16 |

| 2 | Mechanical Properties of TMT bar | 600mm/30 minutes | As per IS1786-2008 | Universal Testing Machine | IS 1608 & IS 1599 | Reprocessed | MSAF/QAD/RMD/16 |

| 3 | Chemical Properties of Billet | First And Last Billet of Every Sequence | %C,%Mn,%S,%P | Spectrometer | IS 2830 | Reprocessed | MSAF/QAD/RMD/19 |